Hidden Heroes: Calmmoon Rail

Reduction of noise pollution in rail traffic

SEKISUI offers a comprehensive product range in Europe, which is a vast array of innovative high-performance materials for applications in four different business sectors: mobility, electronics, medical & diagnostics, and construction & infrastructure. With the series “Hidden Heroes”, we are taking a closer look at SEKISUI’s portfolio and offer deep but simple insights into the products of the European companies. Today, we will have a look at Calmmoon Rail.

Travelling by train is an exciting experience for many. For others, it is simply an opportunity to get to their destination in a peaceful and relaxed way. Good facilities play a large role in this user experience, but we rarely talk about the importance of the infrastructure surrounding it. This is where SEKISUI’s product Calmmoon Rail comes into play.

Clever technology, long service life

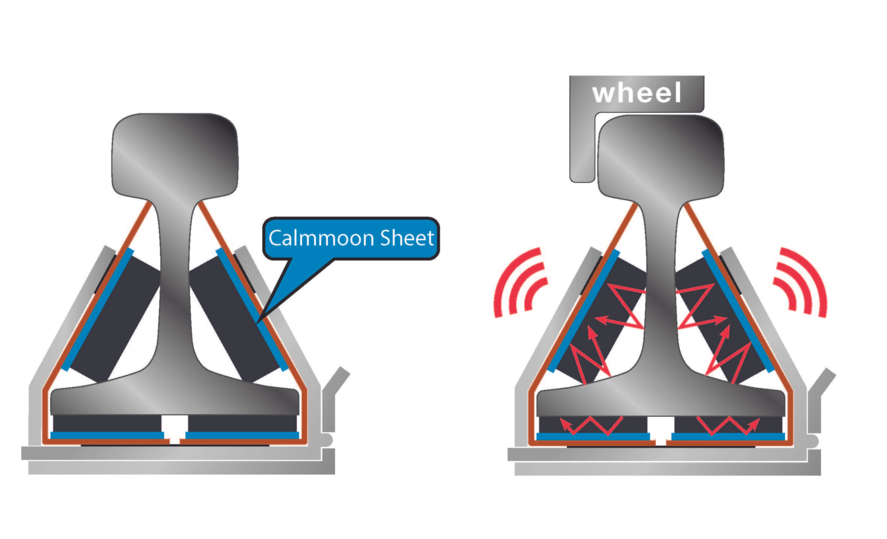

Calmmoon Rail wraps the rails with elements made of thin steel sheet, on which SEKISUI's Calmmoon technology is glued to reduce the airborne sound and vibration energy of the steel sheet. On top of this, there is a sound-absorbing foam attached permanently. The Calmmoon noise damping plate is the key technology of the system: thanks to its material composition it converts the sound energy emitted by the track into heat. Calmmoon is a synthetic resin layer that SEKISUI first introduced in 2002. In addition to rail construction, it is also used in shipbuilding.

But how does the technology actually work in rail construction? The sound insulation of the rail web does not reduce the vibration energy of the rail, but the emission of the airborne sound of the rail. The rail emits its vibration energy which is caused by the train passing over it as unchecked airborne sound. Calmmoon Rail very effectively reduces the emission of this airborne sound to the environment by forming a 'shroud' around the rail. This sheathing serves as a noise-suppressing "mini-sound screen". Two clips per rail in the space between two sleepers ensure that the rail web noise shield is permanently and securely attached to the rail, both during rail operation and track maintenance work.

Tests showed that Calmmoon Rail reduces rail noise by an average of three decibels – and that of five different damping technologies on the rail, only Calmmoon Rail meets the specifications with an average noise reduction of 3 dB (according to report of DB Netz AG 2012). This makes the lives of residents living near the rail track more pleasant – as well as the journey for train passengers.

Simple installation and convincing results

SEKISUI delivers the elements to be installed on pallets in units of 10 sleeper sections. Rail construction workers manually spread the pallets along the track to be shielded before installation and remove the ballast under the rails to a depth of only ten centimetres. This allows the shielding elements and the fastening clips to be installed easily – and the two shielding elements are brought up against the rail on both sides in the area between two sleepers until they rest against the rail. The clips are attached one after the other, and the removed ballast is returned to its original place by hand.

The maintenance and servicing of Calmmoon Rail is very simple: If necessary, Calmmoon Rail can be removed easily and quickly by loosening two clips per rail and section between the sleepers. After completion of the planned work, the elements can be quickly and easily reinstalled. Professionally carried out maintenance work such as tamping, rail grinding, or the use of a ballast plough does not affect the quality of Calmmoon Rail. As of today, Calmmoon Rail is already installed on 80 kilometres in Germany.